Vision Innovation that considers the environment and people

In plastic manufacturing, innovative improvements

Benefits of the Product

Environmental improvement

By using gas capture and purification technology

for harmful gases generated during the melting of plastic resin,

we improve the external environment and ensure workers' health rights

Productivity improvement

By eliminating moisture and gas,

which are chronic defects in injection molding production, product durability is improved,

and defect rates are reduced.

Energy saving

With the moisture removal function, resin drying time is reduced,

and production time is shortened,

allowing for energy savings.

Product Introduction

Custom products designed for existing injection molding machine specs.

Customizable products for specifications with existing injection molding machines

Designed for your injection molding machines,

it works by changing the nozzle and

available in small, medium, and large sizes

Reduction in production costs

Reduction in production costs

Removing gas and moisture reduces defect rates.

Defective products and sprue can be recycled as up to 50% material.

Less use of desiccant and hopper dryers cuts drying time, reducing electricity and carbon energy use.

Product installation and After-service available

Product installation and After-service available

We offer product installation

and after-sales support, including training.

After-sales service is available for any issues.

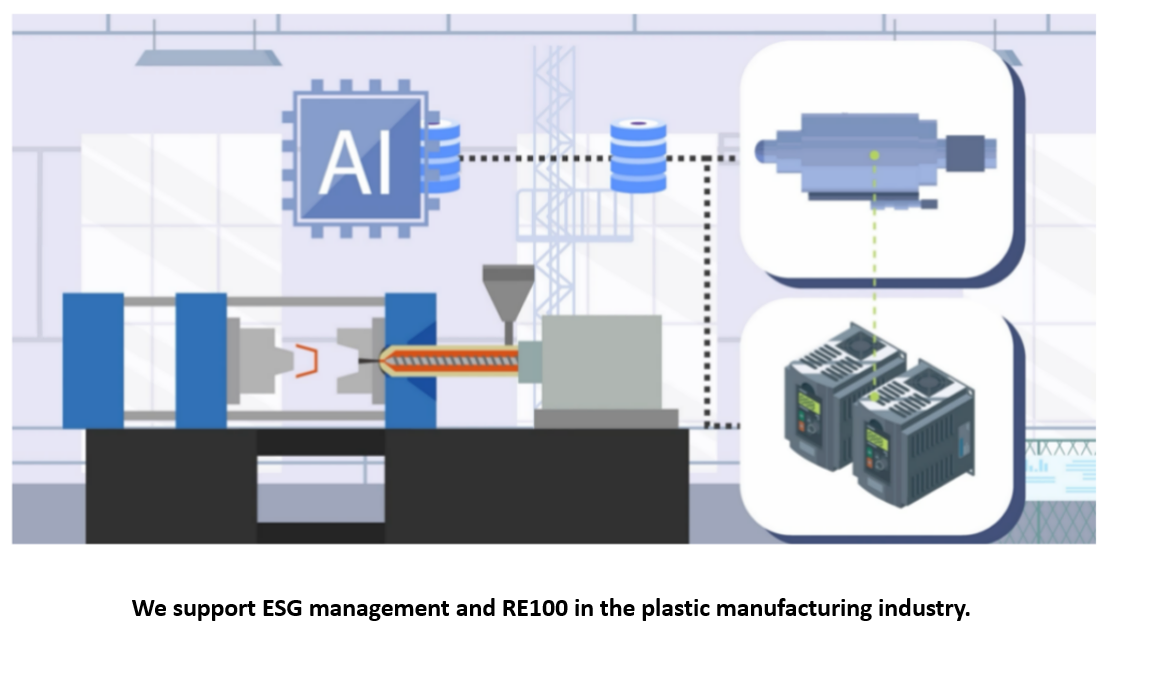

Support for ESG and RE100

Support for ESG and RE100

Achieving waste, electrical, and carbon energy reduction.

Carbon-based gases are captured and purified during injection molding.

Our Team

WE ARE VISION INNOVATION

Our team, consisting of 12 researchers,

is divided into four departments: Management Support,

R&D, Production Technology, and Quality.

In collaboration with advisory committees

in technology, management, and investment, we are leading innovation and shaping a new paradigm in plastic injection molding manufacturing.

Company Certifications

R&D Department / ISO 9001, 14001, 45001 Certifications

Certified as a Materials, Parts, and Equip Company / 3 Registered Patents

Venture Certification (R&D Type) / Root Company Confirmation / Collaboration Company Selection Certificate